Production Process Of Blow Molding Kayaks

Share

Introduction:

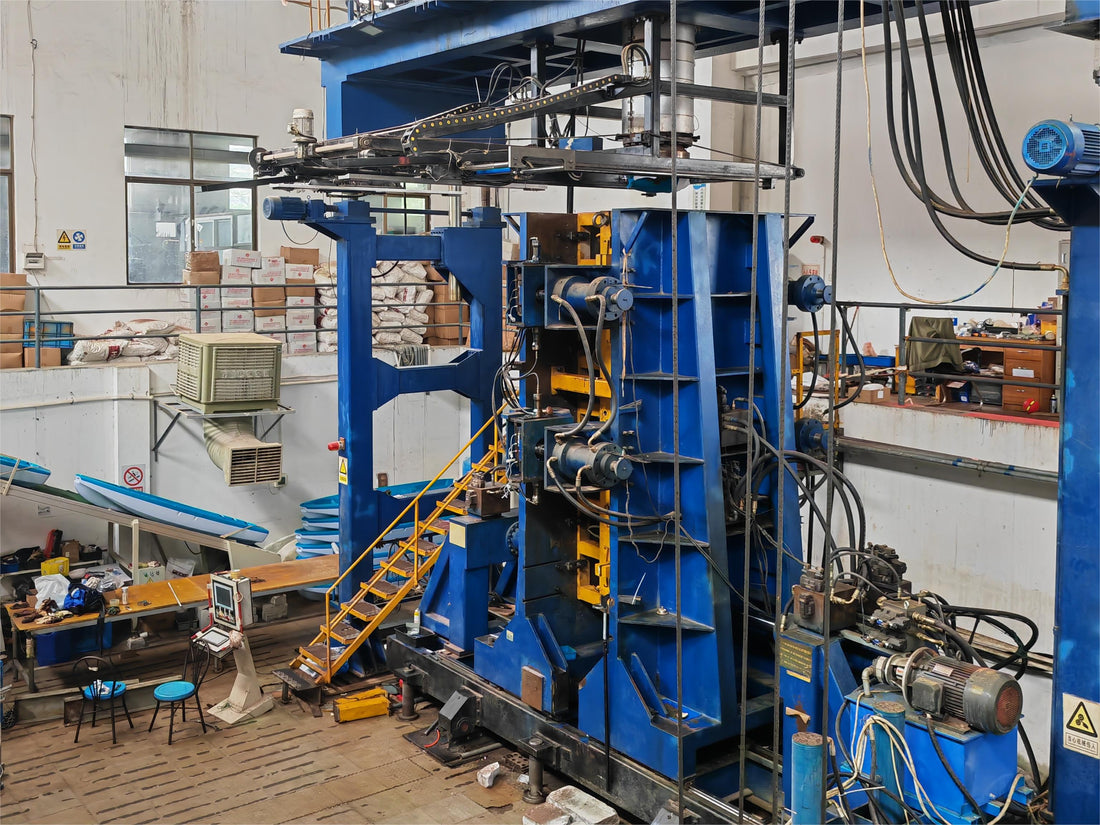

Blow molding kayaks have gained significant popularity in recent years due to their lightweight, durable, and cost-effective nature. The production process involves a unique method called blow molding, which ensures the creation of seamless, robust kayak hulls. In this article, we will delve into the intricacies of the production process and highlight the distinctive features that make blow molding kayaks stand out in the world of watercraft.

Production Process:

1. **Material Selection:**

The process begins with the careful selection of high-density polyethylene (HDPE) or similar materials known for their excellent strength-to-weight ratio. These materials provide the necessary durability to withstand the rigors of water activities.

2. **Mold Preparation:**

A kayak mold, typically made of aluminum or other suitable materials, is prepared according to the desired kayak design. The mold consists of two halves, representing the upper and lower sections of the kayak. The mold's precision is crucial to achieving consistent kayak shapes.

3. **Extrusion and Parison Formation:**

The selected plastic material is then heated and extruded into a tubular shape called a parison. This parison is essentially a hollow tube of molten plastic that will form the basis for the kayak's hull.

4. **Mold Closure:**

The mold halves are brought together, enclosing the parison within the mold cavity. This process ensures that the molten plastic takes on the shape of the kayak mold, creating a detailed and seamless hull.

5. **Blow Molding:**

Compressed air is introduced into the parison, causing it to expand and take the shape of the mold. This controlled inflation results in a hollow kayak hull with a uniform thickness and excellent structural integrity.

6. **Cooling and Solidification:**

Once the kayak hull has taken its final shape, it undergoes a rapid cooling process to solidify the plastic. This ensures that the kayak maintains its structural integrity and the desired form.

7. **Trimming and Finishing:**

The excess plastic, known as flash, is trimmed away, leaving a clean and polished kayak hull. Any additional features, such as mounting points, handles, and seat attachments, are also integrated into the kayak during this stage.

8. **Quality Control:**

Each blow-molded kayak undergoes rigorous quality control checks to ensure that it meets the required standards for strength, durability, and overall performance. This step ensures that only high-quality kayaks reach the market.

Characteristics of Blow Molding Kayaks:

1. **Lightweight Design:**

Blow molding results in kayaks that are inherently lightweight without compromising strength. This characteristic makes them easy to transport and maneuver on the water.

2. **Durability:**

The use of high-density polyethylene in the blow molding process imparts exceptional durability to the kayaks. They can withstand impact, abrasion, and exposure to UV rays, ensuring a long lifespan.

3. **Seamless Construction:**

The seamless construction of blow-molded kayaks eliminates the need for joints or seams that could compromise structural integrity. This results in a smoother and more hydrodynamic hull.

4. **Affordability:**

Blow molding is a cost-effective manufacturing process, allowing for the production of kayaks at a competitive price point. This affordability makes them accessible to a broader range of enthusiasts.

5. **Versatility in Design:**

The mold used in the blow molding process can be customized to create a variety of kayak designs. This versatility allows manufacturers to cater to different preferences and styles, from recreational kayaks to specialized models.

6. **Environmentally Friendly:**

HDPE, the primary material used in blow molding kayaks, is recyclable. This environmentally friendly aspect aligns with the growing demand for sustainable and eco-conscious products.

7. **Buoyancy and Stability:**

The uniform thickness achieved through blow molding contributes to the buoyancy and stability of the kayak. These characteristics enhance the overall safety and performance of the watercraft.

Conclusion:

Blow molding has revolutionized the production of kayaks, offering a balance of affordability, durability, and design versatility. The seamless construction, lightweight nature, and eco-friendly materials used in the process contribute to the growing popularity of blow-molded kayaks among water sports enthusiasts. As technology advances, it is likely that the production processes will continue to evolve, further refining the characteristics of these innovative watercraft.